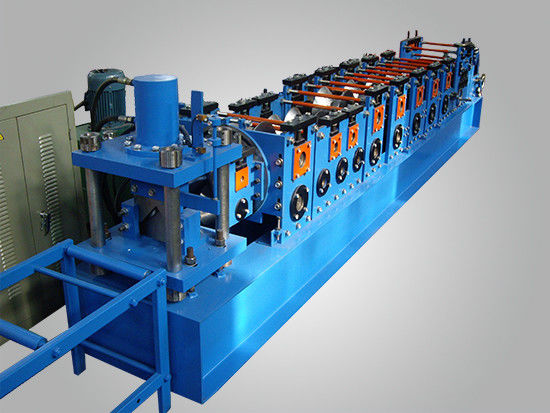

Material Galvanized steel Thickness1.0~2.0mm L Racking Roll Forming Machine Speed 5-12m/min

1. Technical Parameter

- Running material: Galvanized steel Thickness – 1.0~2.0mm

- Forming speed: 5-12m/min

- Forming steps: 9 steps

- Roller material: Gcr15

- Material of principal axis: 45# steel

- Sprocket wheel: 45 steel high-frequencies quench; distance 25.4. Quantity: 13pcs

- Motor power: 5.5 KW

- Cut-off system: Adopts hydraulic pressure drive, cut off after forming.

- Hydraulic system electrical machinery power: 3KW

- Hydraulic system pressure: 10Mpa

- PLC Control system: Brand of Siemens Encoder is Japanese Omron brand; the Inverter is Siemens

- brand

- Overall Dimension of the main forming machine:4000mmX700mmX900mm

- Total weight: 3 ton approximately

- Un-coiler: 3 Ton capacity of manual un-coiler

- the punching press machine for the holes

- Power supply: 220V 60HZ, 3 phase

2. Working Flow

Un-coiler ------ Feeding device ---Punching --- Roll forming ----- PLC control --- Hydraulic cutting----

Run out table

3. Machine Components

| 3 ton passive decoiler |

1 set |

| servo feeding |

1 set |

| punching press machine |

1 set |

| Main roll forming machine |

1 set |

| PLC control box |

1 unit |

| Hydraulic station |

1 unit |

| Out table |

2 Units |

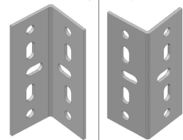

4. Profile

4. Machine Photo

5.Our After-Sales Service Commitments

Sussman hereby solemnly promises: We implement the “three guarantees” service policy for any equipment sold by Sussman, provide free of charge installation guidelines, commissioning and maintenance of the equipment, training of the Buyer’s relevant Operators; and provide technical requirements for the installation and operation of the equipment, technical layout diagrams and other related information, provide a lifetime supply of maintenance and spare parts

The detailed measures are as follows:

1.Guidelines for installation and commissioning of equipment:

Based on the actual situation, to assist and guide the Buyer and Buyer’s technical personnel in the overall installation location, the installation of equipment, and provide Buyer with answers to their questions and related issues;

2.Provide training for operation and maintenance personnel:

Based on the Buyer’s request, Sussman will provide free of charge training of the operation and maintenance personnel;

a) The User (Buyer) can send their operation and maintenance personnel to our factory for learning and training;

b) When Sussman is doing the installation and test running of the equipment for the Buyer, the Buyer can send their personnel to participate.

3.If failure occurs in any of the machines during the “three guarantees” period(one year), then, upon the Buyer’s request, Sussman will eliminate the failure;

4. Sussman will inform all its Buyers about any upgrades and significant product improvements. Sussman will provide equipment modifications based on their costs. Sussman will provide Buyers with high-quality after-sales services in a careful and responsible attitude, provide very strong guarantee for the Buyer’s normal production.

We provide quick and satisfactory customer service, and promise to respond within 24 hours after receiving your complaints by phone or email

6.FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome your visit us and test machine by yourself in our factory.

6) Q: Do you sell only standard machines?

A: No. Most machines are made to order.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!