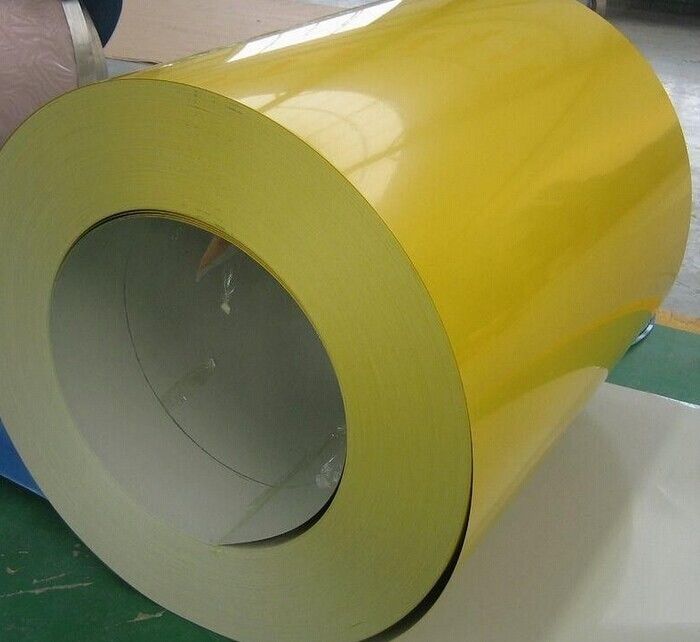

PPGI PPGL Color coated Steel Coils Prepainted Galvanized Galvalume

Quick Detail:

|

Name

|

Special color steel

|

Brand Name

|

Dragon

|

|

Test Item

|

STANDARD

|

|

T Bending

|

OT-3T

|

|

Pencil Hardness

|

HB

|

|

Impact

|

≥9J

|

|

Mek(Time)

|

≥100

|

|

Salt Spray

|

≥720hr

|

|

Acid Stability

|

5% HCL solution soak 48Hr,no bubbles,discoloration,no peeling

|

|

Alkali Resistance

|

Soaked in 5% NaOH solution 48Hr,no bubbles,discoloration, no peeling

|

Description:

|

Specification

|

|

Base Material

|

(1)HDGI (2)ALUZINC (3)CR

|

|

Grade

|

SGCC,DX51D,ASTM A653,EN10142,S350GD,etc.

|

|

Thickness

|

0.2~1.2mm

|

|

Width

|

≤1250mm

|

|

Zinc Coating

|

60-200g/m²

|

|

Pattern

|

Wood imitation,Marble,Hairline,Brick,and Camouflage series,etc.

|

|

Coating

|

Top coat 5 + 15um , 5+ 20um, Back coat: 5-15um

|

|

Paint

|

PE,PVDF,SMP,HDP

|

|

Coil Id

|

Ф508mm

|

|

Coil Weight

|

≤6t

|

|

Production Capacity

|

50,000 t/month

|

Applications:

1. Construction: roof and roof component, outside walls of civilian and industrial buildings, garage doors and window blinds., soundproof walls, pipes and modular housing

2. Houshold appliances: washing machine, refrigerator, television, gas furnaces, air conditioner and ventilation system, microwave oven, Vacuum cleaner, solar water heater electrical cabinets and other

3. Transportation: car ceiling, auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, the ship bulkhead, highway fence.

4. Industry: industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

5. Furniture: lampshade, counter, signboard and medical facility etc.

6. Agricultural: Other barns, sheds, silos, pipelines and other greenhouse use: heat insulation cover, heat exchangers, dryers, warm water, etc.

Competitive Advantage:

. Reliable and stable Quality

. Reasonable Price

. Fast delivery time

. More Than 10 Years export experience

Quality Control.

Prior to coating mainly has the following several inspection process control:

(1) check the strip surface treatment before it through the test and analysis of surface defects and the shape of the.

(2)check the effect of the metal surface degreasing cleaning inspection.

(3) check the strip surface chemical liquid film thickness is in accordance with the provisions of the national or industrial standards.

(4) check whether it meets the requirements of steel strip surface coating substrate in the surface temperature, humidity areas.

(5) check models, specifications, paint and thinning of the viscosity before into the machine.

(6) check the coating chamber temperature.

Coating construction process control mainly has the following several inspection process:

(1) the wet film thickness of bottom, paint coatings.

(2) whether there is leakage with or without continuous absence of wet film.

(3) the head of each roll coating and production line speed ratio is in accordance with the process requirement.

(4) the drying temperature curing furnace sections.

Control after coating has the following several major inspection:

(1) surface state inspection coating, including whether there are surface defects, gloss and color etc..

(2) the national industry standard or check the total dry film thickness can reach the design requirements

(3) the adhesion and coating inspection on a substrate.

(4) according to other performance quality standard inspection coating.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!